Plastic to Fuel – Pyrolysis Reactor

Plastics are malleable polymers that can deform very strongly. These are a number of organic compounds, most of which are synthetic and come from petrochemicals. Some plastics are also semi-synthetic and can be made from renewable raw materials.

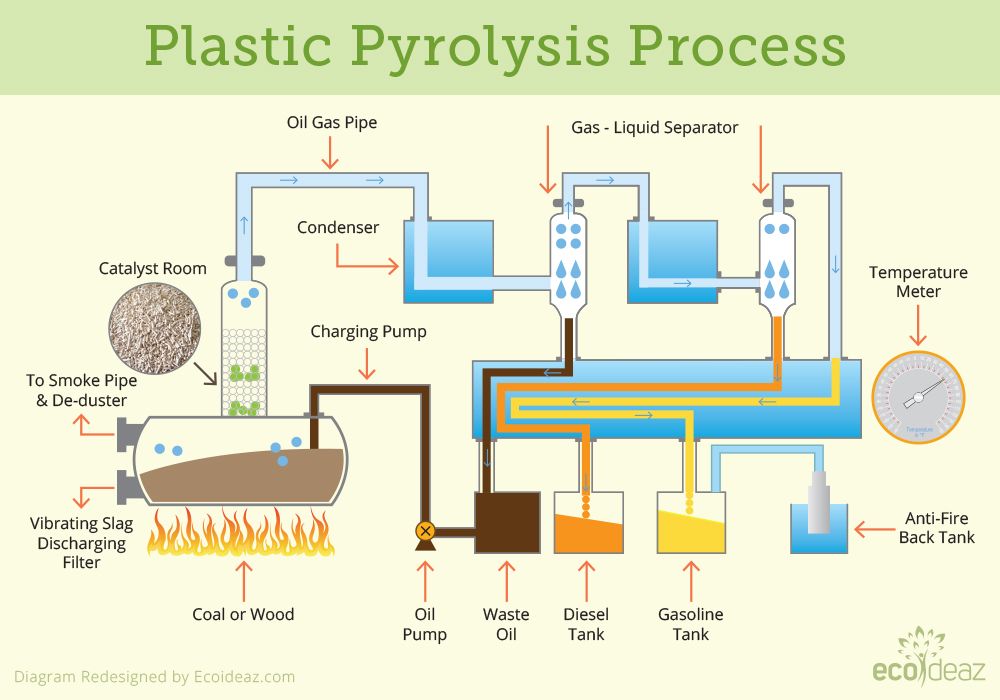

The disposal of plastic waste is a major problem, so it has been repeatedly recommended to recycle the plastic materials. Pyrolysis is a way to recycle the plastic material. The basis is that a pyrolysis of plastic can be performed to produce oil. This oil is then used as fuel. The pyrolysis process involves the thermal degradation of plastic at different temperatures in the absence of oxygen.

The pyrolysis chamber is loaded with plastic. The reaction temperature can be in the range of 200 à 900 ° C, based on the quality of the liquid oil, which is desired later as a product. The raw material is first melted and then evaporated.

The vapours are then fed in series to capacitors to condense them into different fuel types.